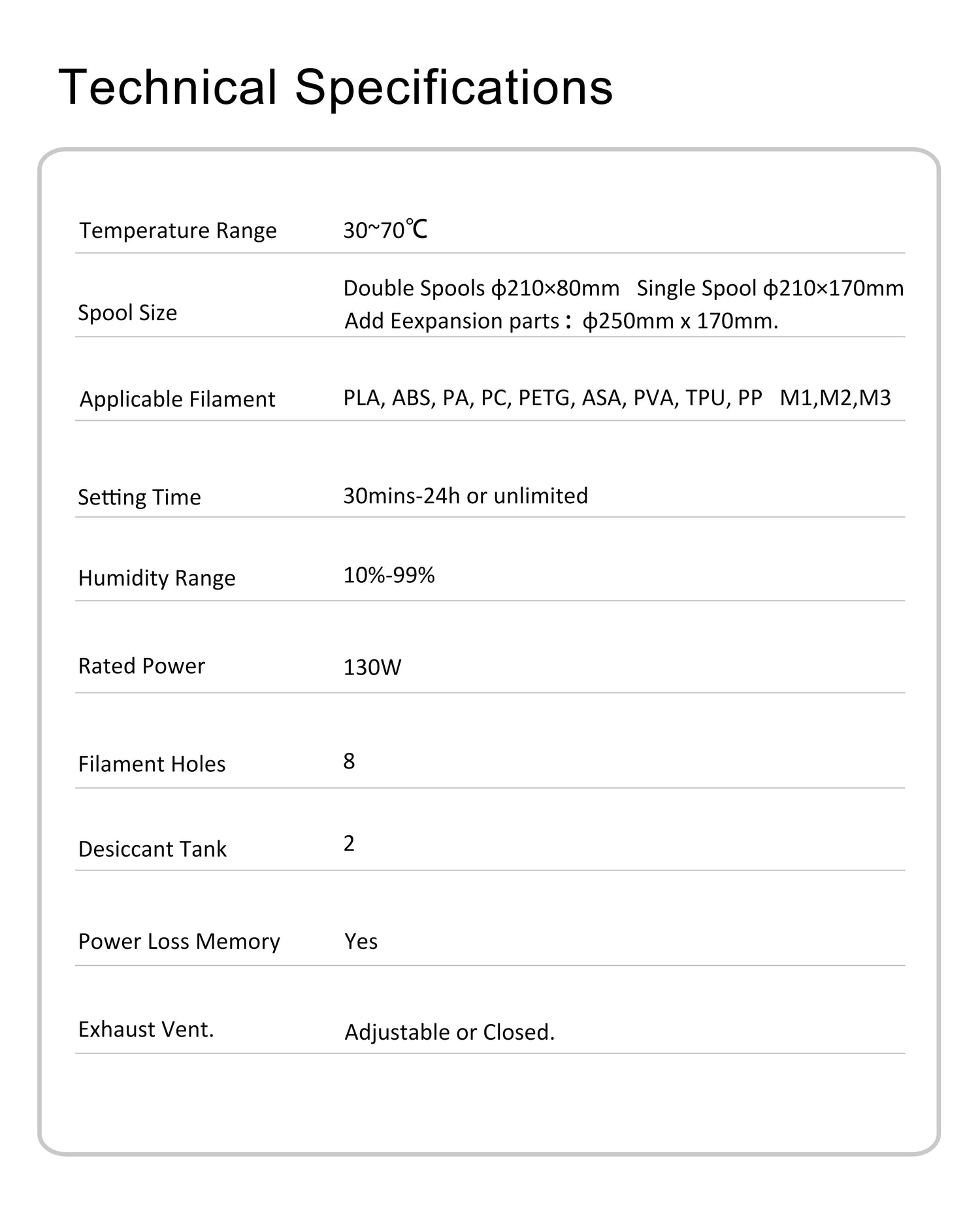

In order to make Polyphemus more convenience to use, it has features an adjustable exhaust vent located on the top of the lid. When heating is not required, you can close the exhaust vent to control the internal humidity and temperature. This helps maintain the desired environmental conditions while avoiding excessive drying.

Furthermore, POLYPHEMUS provides a dedicated compartment where you can place desiccants. The desiccants absorb moisture from the air, further ensuring a dry environment for the filament. You can choose suitable desiccants and replace them in a timely manner based on their lifespan.

The combination of these features enhances the operational flexibility and filament protection capabilities of POLYPHEMUS, enabling you to achieve optimal drying results.

Regarding Fire Safety

Similar to Cyclopes and Easdry, Polyphemus also utilizes the safer PTC heating element. Without fan cooling, the internal temperature can only rise to approximately 200℃, which is safer compared to PI heating elements that can potentially cause open flames. Additionally, all the external casings of Polyphemus are made from the highest fire resistance grade material, V0 level.

Furthermore, the system has real time monitoring of the internal fan. In the event of a fan failure, the system will automatically trigger an alarm and shut down. Safety is our top priority when it comes to this product.

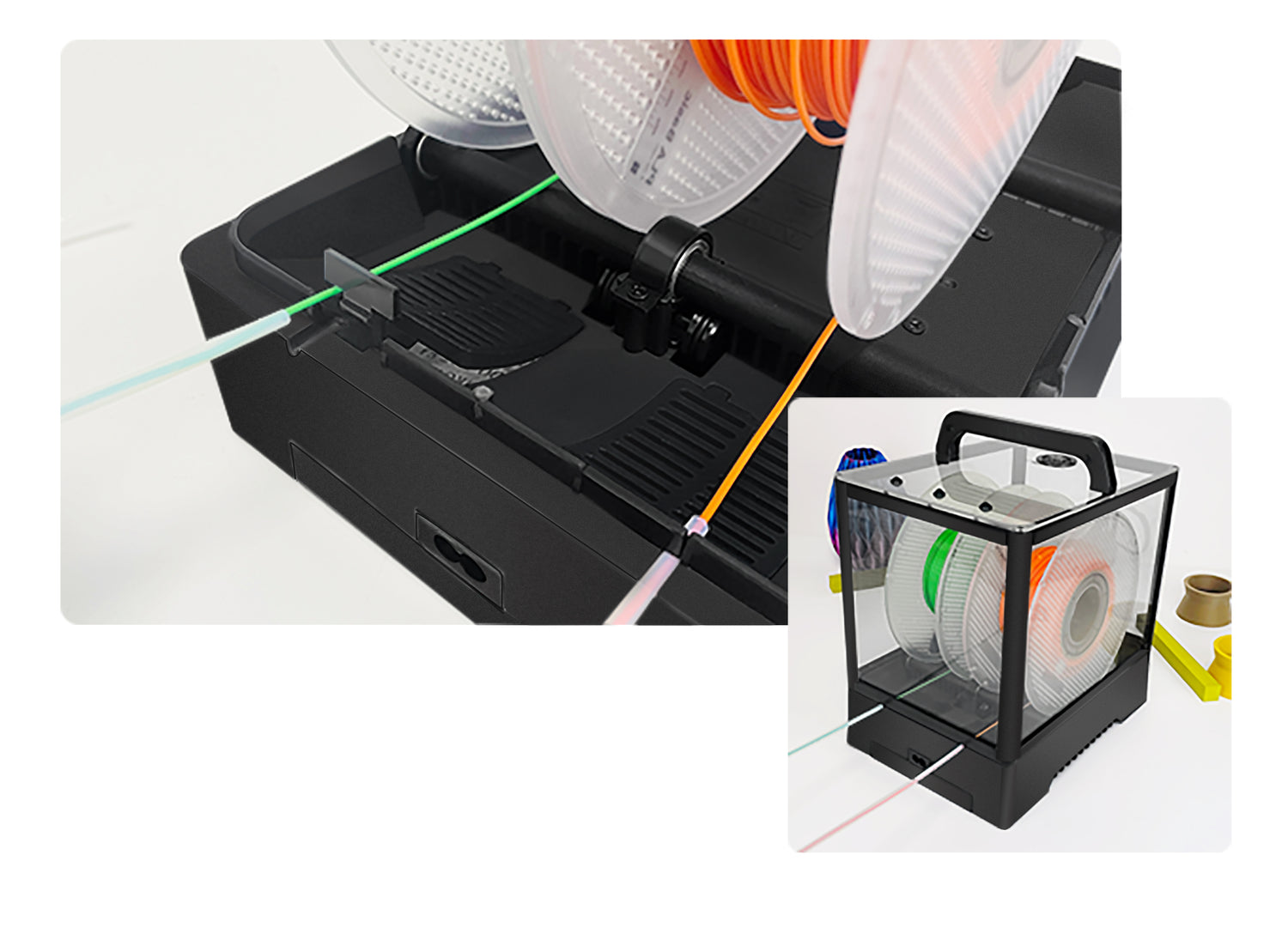

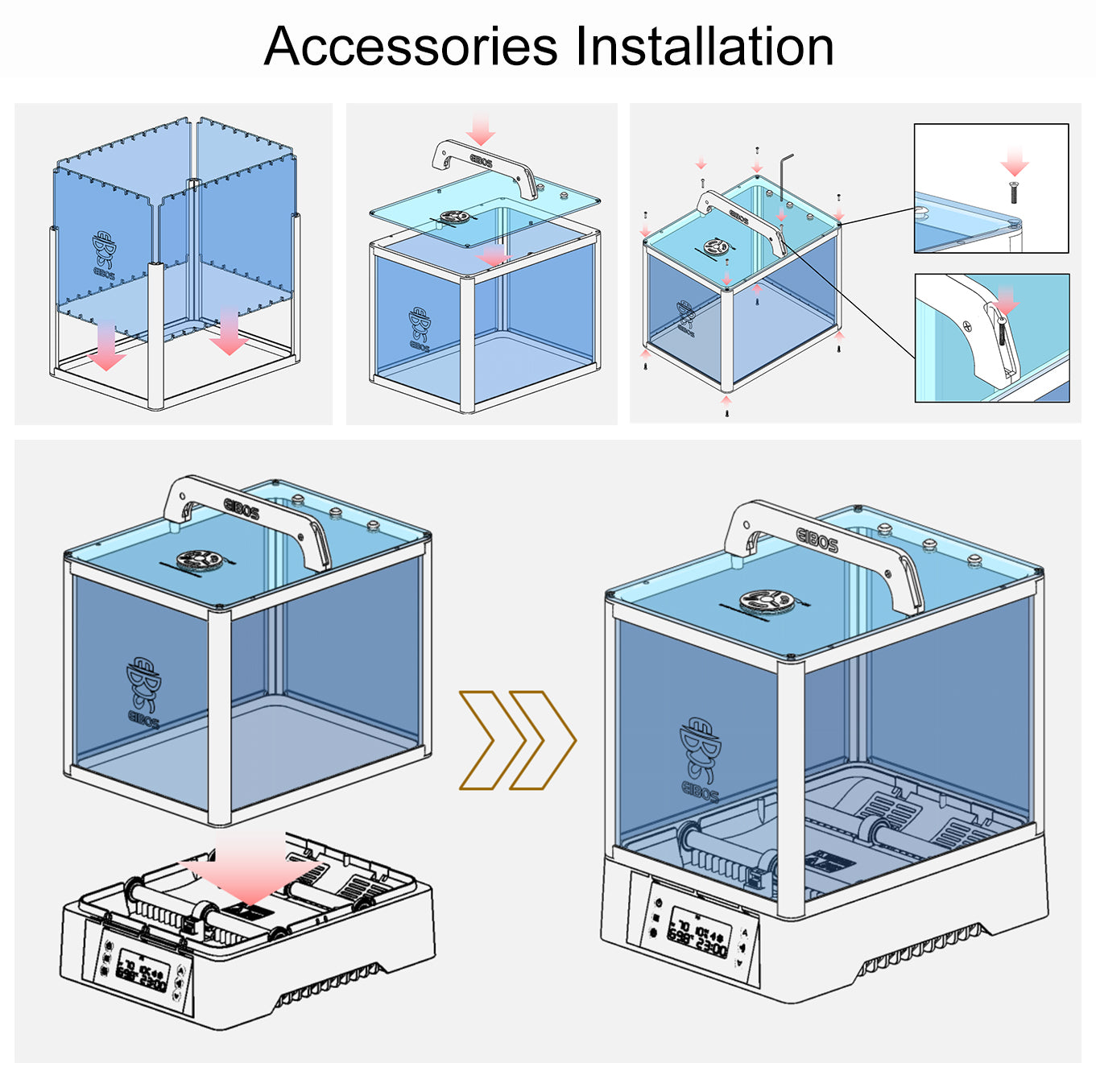

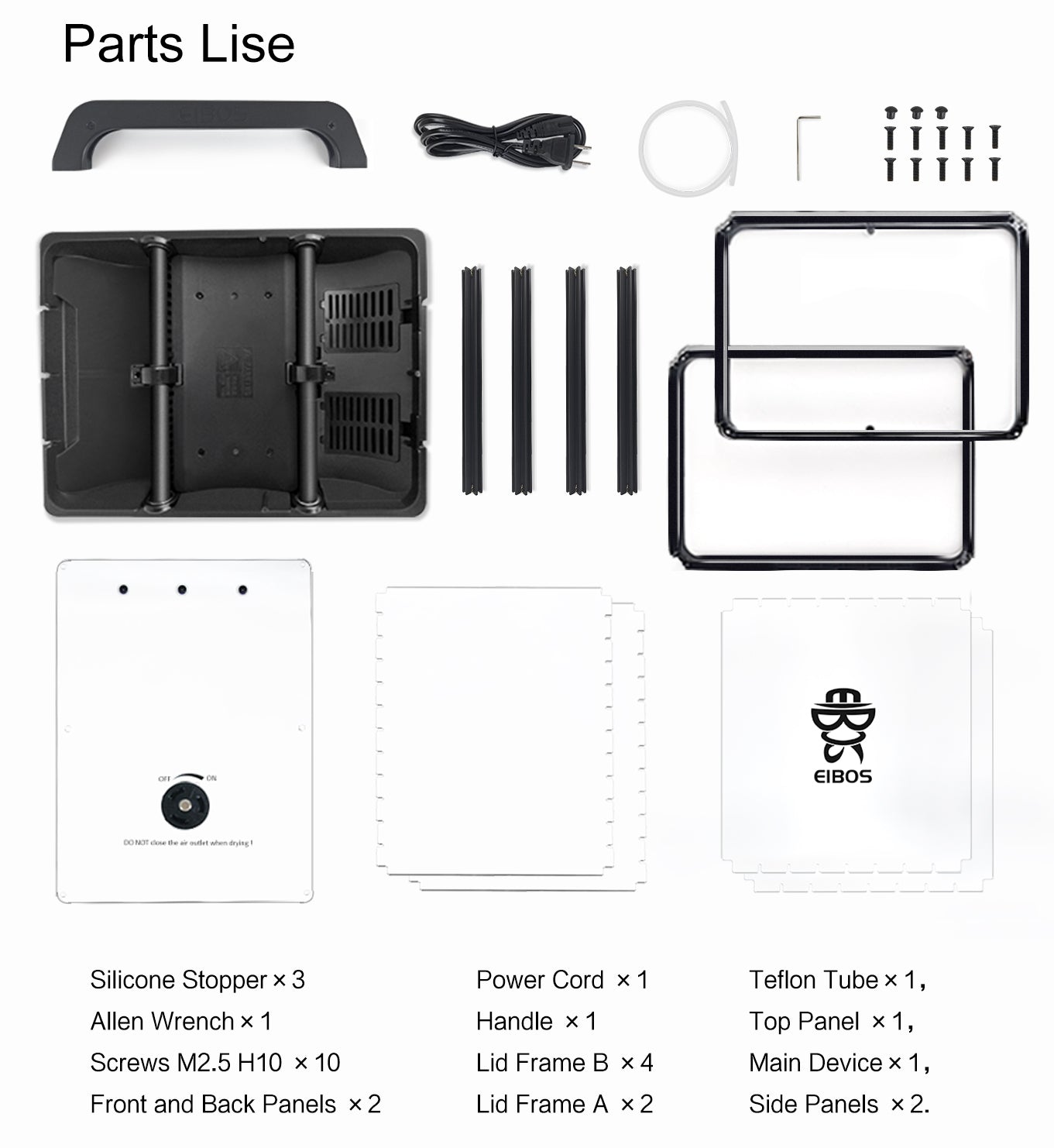

To facilitate easy connection to the 3D printer, Polyphemus is equipped with a total of 5 filament outlets on the front and back. These outlets allow you to connect the filament to the printer without the need for additional piercing or modifications. Even if the filament is already connected to the printer, you can directly place it inside the drying chamber of Polyphemus. Additionally, there are 3 wire outlets on the top of Polyphemus, allowing you the flexibility to position the wires in any desired direction.The handle on the top of Polyphemus allows you to easily open the top cover.

After installing the expansion module, Polyphemus expands from its original 210mm diameter to accommodate a larger 250mm diameter. This increase in size allows for the capacity to hold up to 3kg of filament.