Introduction

3D printing is a process that creates three-dimensional objects by depositing successive layers of material on top of each other. It is also known as additive manufacturing. The most common materials used in 3D printing are thermoplastic filaments, such as PLA and ABS. Moisture can accumulate in the filament, causing problems during printing, such as warping and poor adhesion. A filament dryer is a device that uses heat and a controlled environment to remove moisture from the filament, ensuring that it is dry and ready for use in 3D printing. This can improve the quality of the final printed object and reduce the likelihood of printing failures.

Many popular materials used in 3D printing, such as PLA and ABS, are hygroscopic, meaning they can absorb moisture from the atmosphere. Moisture in the filament can cause the filament to become brittle and difficult to work with and can cause problems during the extrusion process. When the filament is heated, the moisture turns into steam, which can cause bubbles or voids to form in the printed object. Moisture can also cause problems with adhesion between layers, resulting in a finished product that is weaker and less durable than it should be.

Controlling moisture in 3D printing filaments is crucial for producing high-quality, accurate prints. By taking steps to prevent moisture from accumulating in the filament, such as storing it in a dry environment or using a filament dryer, it is possible to produce high-quality prints that meet the needs of the application. Additionally, controlling moisture in 3D printing filaments can reduce waste and minimize the amount of time and materials needed to produce a finished product, making 3D printing a more efficient and cost-effective manufacturing process.

What is Hygroscopic?

Hygroscopicity is the ability of materials to absorb and retain moisture from the air, which can impact their performance and behavior in various applications. Many materials used in 3D printing are hygroscopic, meaning they can absorb water vapor from the air and become more difficult to work with. Moisture in the filament can cause problems during printing, such as warping, cracking, and poor adhesion between layers. Additionally, the presence of moisture in the filament can cause defects in the printed object, such as bubbles or voids, and can result in a finished product that is weaker and less durable.

The hygroscopicity of 3D printing filaments can be affected by various factors, including the chemical structure of the material, temperature, humidity, and storage conditions. The chemical structure of materials used in filaments can impact their hygroscopicity, with materials containing polar functional groups being more hygroscopic. Temperature can affect the ability of materials to absorb moisture from the air, while higher humidity levels result in a greater concentration of water vapor in the air and can increase the amount of moisture absorbed by the filament. Proper storage conditions, such as storing filaments in a sealed container with a desiccant or in a dry environment, can reduce the amount of moisture absorbed by the filament.

Water molecules play a crucial role in hygroscopicity and diffusion. When a hygroscopic material is exposed to water vapor in the air, water molecules can be absorbed into the material through diffusion. Diffusion occurs because water molecules tend to move from areas of high concentration to areas of low concentration until an equilibrium is reached. The rate of diffusion is influenced by temperature, humidity, and the concentration gradient between the material and the surrounding air. Materials with polar functional groups are more likely to attract water molecules and are therefore more hygroscopic.

Controlling moisture in 3D printing filaments is crucial for producing high-quality prints that meet the needs of the application. By taking steps to prevent moisture from accumulating in the filament, such as proper storage or using a filament dryer, it is possible to produce high-quality prints that are free from defects. This can also reduce waste and minimize the amount of time and materials needed to produce a finished product, making 3D printing a more efficient and cost-effective manufacturing process.

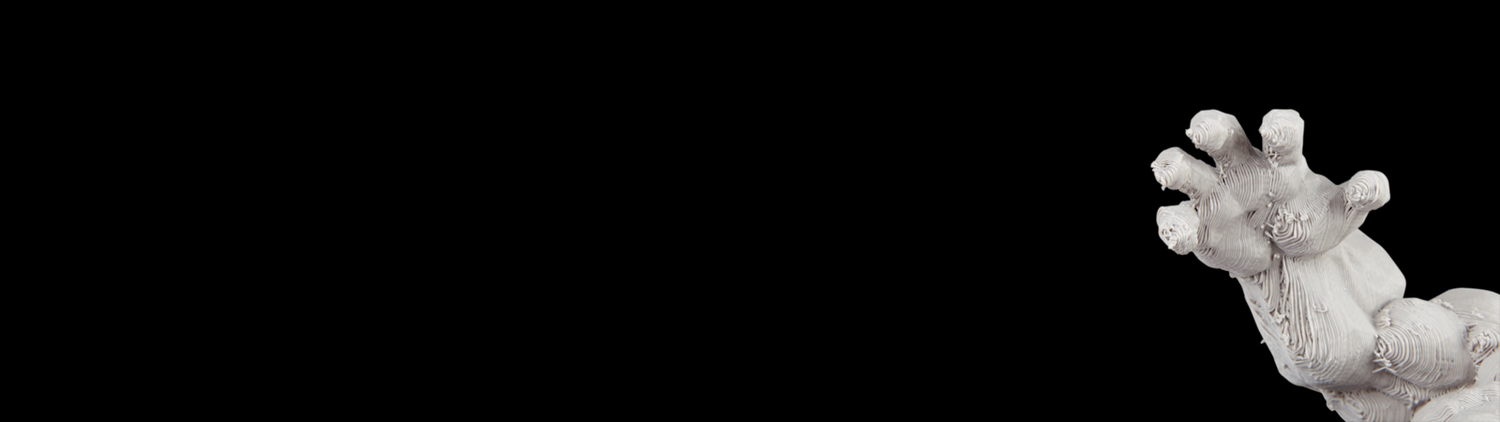

The working principle of EIBOS Filament dryer.

EIBOS filament dryer is an active filament dryer which is different from passive filament dryer. It has features a heating element and a fan that works together to circulate the heated air around the filament spool. This helps to remove any moisture that may be present in the filament. The temperature and time settings can be adjusted according to the specific requirements of the filament being dried. The EIBOS filament dryer is compatible with a wide range of 3D printing filaments, including PLA, ABS, PETG, Nylon, TPU, and more. It can accommodate filament spools from different brands and can dry up to two 1KG spools at the same time. The dryer is designed to operate at a temperature range of 35-70°C, which is ideal for most types of filaments.

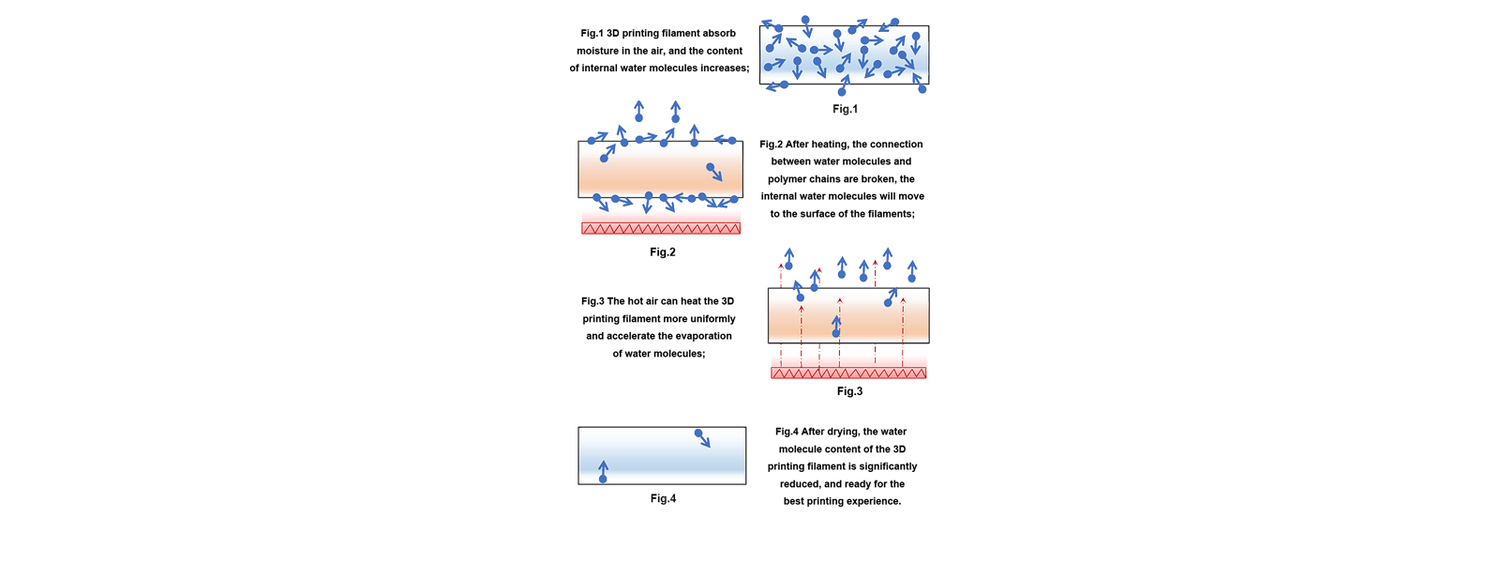

In the laboratory, we used the OHAUS MB45 Moisture Analyzer to detect the water molecule content of the material under different drying times.

It is obvious that the moisture content for both PLA and PA-CF has drop significantly.

Effects of Water Molecules on 3D Printing Filaments.

The presence of water molecules in 3D printing filaments can significantly impact their mechanical, thermal, and electrical properties. Moisture can cause the filament to absorb water and therefore swell, leading to shrinkage and warping during the printing process that can reduce the dimensional accuracy of the printed object. The presence of moisture can also cause bubbles or voids to form in the printed object, which can weaken its mechanical properties.

The mechanical strength of the printed object can be reduced if the filament is not dried properly before printing. The drying process can help remove the absorbed water and improve the mechanical properties of the printed object. Various studies have shown that drying the filament before printing can improve the mechanical properties of 3D printed objects made from different filaments.

Water molecules can also affect the thermal properties of 3D printing filaments. The presence of moisture in the filament can lower the glass transition temperature (Tg) of the material. The lower Tg can make the printed object more susceptible to deformation or distortion at elevated temperatures. Additionally, the presence of moisture in the filament can cause the material to degrade at higher temperatures, leading to reduced thermal stability.

To ensure high-quality prints, it is essential to control the moisture content of 3D printing filaments. Proper storage and handling of filaments can help prevent the absorption of moisture.

Using a filament dryer can also help remove moisture from the filament before printing. By controlling the moisture content of filaments, it is possible to produce high-quality 3D printed objects with improved mechanical, thermal, and electrical properties.

The effects of water molecules on different types of filaments can vary depending on the material properties of the filament. Some filaments are more hygroscopic than others, meaning that they are more likely to absorb moisture from the surrounding environment. The impact of moisture on filament properties can also depend on the specific printing conditions, such as temperature and humidity.

Here is a brief comparison of the effects of water molecules on some commonly used 3D printing filaments:

ABS (Acrylonitrile Butadiene Styrene): ABS is a thermoplastic polymer that is widely used in 3D printing. It is moderately hygroscopic and can absorb moisture from the surrounding environment. The presence of moisture in the filament can cause warping and deformation during printing, leading to poor dimensional accuracy. Drying the filament before printing can improve the dimensional accuracy of the printed object.

PLA (Polylactic Acid): PLA is a biodegradable thermoplastic polymer that is derived from renewable resources such as corn starch or sugarcane. It is less hygroscopic than ABS and is less prone to absorbing moisture. However, the presence of moisture in the filament can still cause issues such as poor adhesion between layers and clogging of the printer nozzle.

Nylon: Nylon is a synthetic thermoplastic material that is known for its strength and durability. It is highly hygroscopic and can absorb moisture from the surrounding environment. The presence of moisture in the filament can cause issues such as warping, deformation, and reduced mechanical properties. Drying the filament before printing can improve the mechanical properties of the printed object.

PETG (Polyethylene Terephthalate Glycol): PETG is a thermoplastic polymer that is known for its strength and toughness. It is less hygroscopic than nylon and is less prone to absorbing moisture. However, the presence of moisture in the filament can still cause issues such as poor adhesion between layers and reduced mechanical properties.